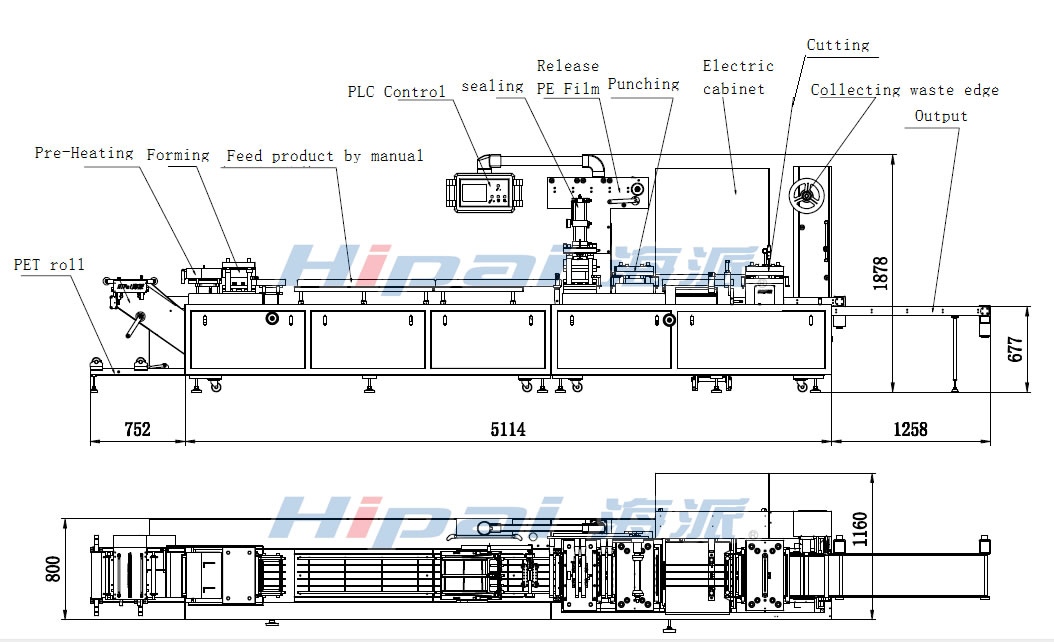

HP-320 intelligent high-yield toothbrush packaging machine

Scope:

It is suitable for paper and plastic packaging of toothbrushes, hardware, stationery, medical equipment (injection, syringe, medicine) and other related products.

Key Performance Structure Features:

The main equipment of this equipment is plastic (PVC/PET) heating, forming, forming blister testing (optional), stroke traction, feeding, lack of material inspection and waste (optional), automatic paper card, paper plastic preheating seal , reheat seal, aircraft hole (optional), random coding (optional), punching and other feature stations.

■ Worm gear reducer drive, overload protection of the main engine, low noise and stable operation.

■ Adjustable stroke size, free to change the size of the block, suitable for multi-species products.

■ It adopts dual-axis positioning and (spline) shaft transmission, and the work is stable and stable.

■ It adopts PLC programmable modular design, which is easy to operate and easy to maintain.

Main technical parameters:

| Punching speed (standard version 150 x 50 x 5mm) one out of two card toothbrush | Paper / plastic 15 times / minute | |

| Production capacity | Paper/plastic 7500 times/hour | |

| Feed stroke optional range | 30-3000mm | |

| Formed area | 300-280mm | |

| Forming depth | Plastic 40mm (Special requirements 50mm) | |

| Forming up/down heating power | 2kw ( x2 ) | |

| Heat sealing heating power | 3.5kw | |

| main motor power | 1.5kw | |

| Total power of the power supply | Three-phase four-wire 380v 50hz (220v 60hz) 11.8kw | |

| Air pump volume flow | ≥ 1m3 / min | |

| Packaging material | Plastic hard sheet (special made of PET structure) | ≤ 0.2-0.5x320mm |

| Paper card / dialysis paper / PE film / aluminum foil | ≤ 320x280x0.5mm / 320x0.02mm | |

| Dimensions | 6080x1160x1800mm | |

| Total Weight | 2500kg | |